1.The basic structure of the bearing

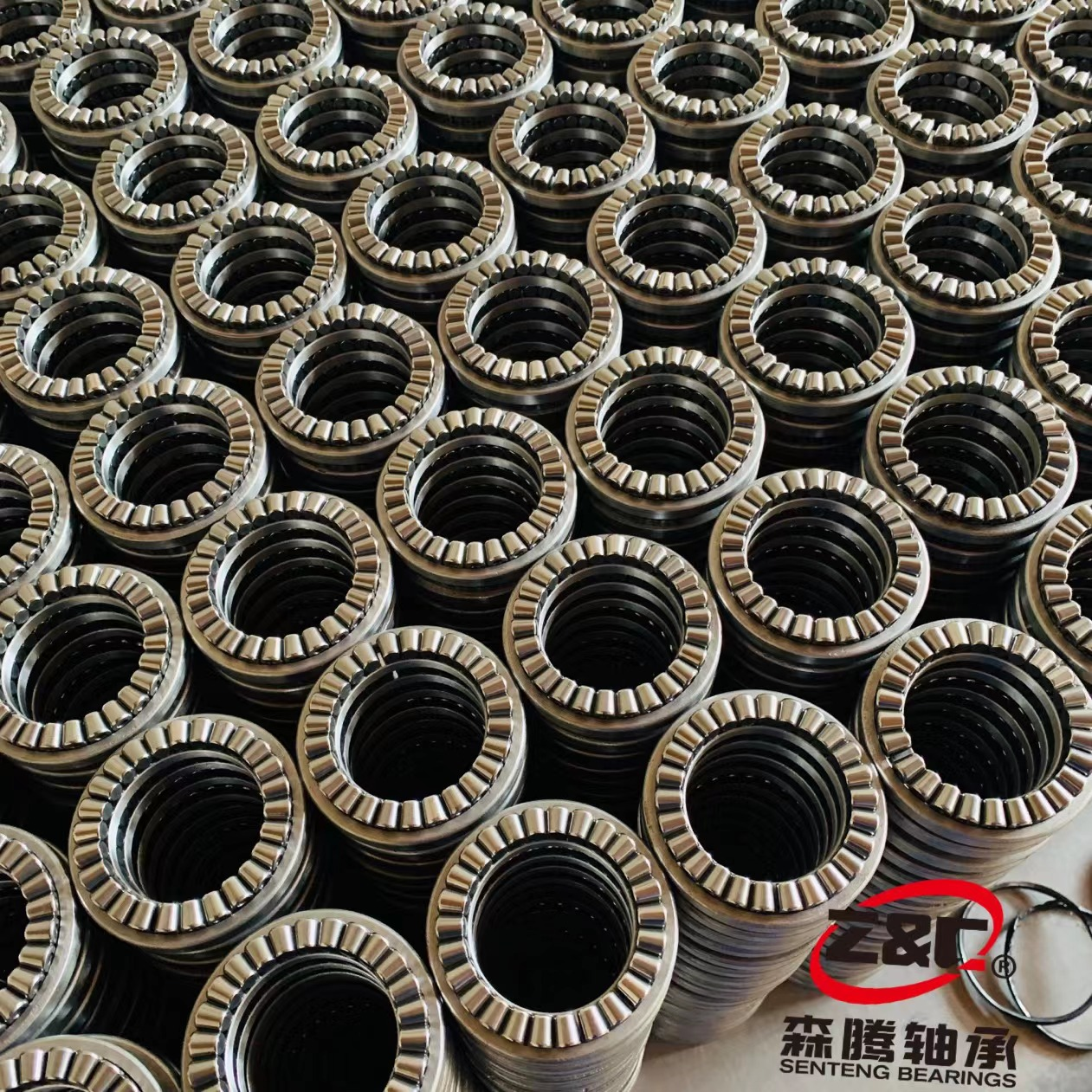

The basic composition of the bearing: inner ring, outer ring, rolling elements, cage

Inner ring: tends to fit tightly with the shaft and rotate together.

Outer ring: It is often matched with the bearing seat in transition, mainly for the function of support.

The material of the inner and outer rings is bearing steel GCr15, and the hardness after heat treatment is HRC60~64.

Rolling elements: With the help of cages, they are evenly arranged in the trenches of the inner and outer rings. Its shape, size and quantity directly affect the bearing’s load-carrying capacity and performance.

Cage: In addition to evenly separating the rolling elements, it can also guide the rolling elements to rotate and effectively improve the internal lubrication performance of the bearing.

Steel ball: The material is generally bearing steel GCr15, and the hardness after heat treatment is HRC61~66. The accuracy grade is divided into G (3, 5, 10, 16, 20, 24, 28, 40, 60, 100, 200) according to dimensional tolerance, shape tolerance, gauge value and surface roughness from high to low. These are ten grades .

In addition, there are auxiliary structures for bearings

Dust cover (sealing ring): prevent foreign matter from entering the bearing.

Grease: Lubricates, reduces vibration and noise, absorbs frictional heat, and increases bearing life.

2. Bearing accuracy grade and noise clearance representation method

The accuracy of rolling bearings is divided into dimensional accuracy and rotational accuracy. The accuracy level has been standardized and divided into five levels: P0, P6, P5, P4, and P2. The accuracy has been improved successively from level 0. Compared with the usual use of level 0, it is sufficient. Depending on different conditions or occasions, the required level of precision is different.

3. Frequently Asked Bearing Questions

(1) Bearing steel

Common types of rolling bearing steel: high carbon bearing steel, carburized bearing steel, corrosion-resistant bearing steel, high temperature bearing steel

(2) Lubrication after bearing installation

Lubrication is divided into three types: grease, lubricating oil, solid lubrication

Lubrication can make the bearing run normally, avoid the contact between the raceway and the surface of the rolling element, reduce the friction and wear inside the bearing, and increase the service life of the bearing. Grease has good adhesion and wear resistance and temperature resistance, which can improve the oxidation resistance of high temperature bearings and enhance the service life of bearings. The grease in the bearing should not be too much. Too much grease will have the opposite effect. The higher the rotational speed of the bearing, the greater the harm. It will cause the bearing to generate a lot of heat when it is running, and it will be easily damaged due to excessive heat. Therefore, it is extremely important to fill the grease scientifically.

4. Precautions for bearing installation

Before installation, pay attention to check whether there is any problem with the quality of the bearing, select the corresponding installation tool correctly, and pay attention to the cleanliness of the bearing when installing the bearing. When tapping, pay attention to even force and tap lightly. After installation is complete, check that the bearings are in place. Remember, do not unpack the bearing until preparations are complete to prevent contamination.

Post time: Oct-08-2022